Description

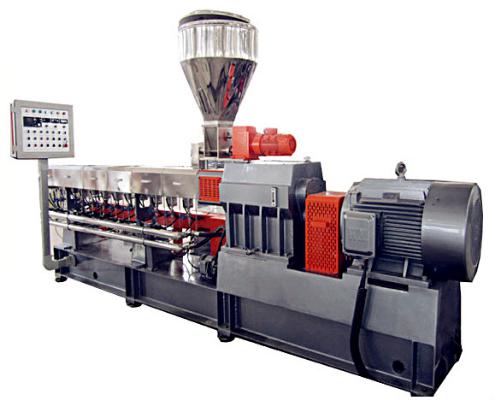

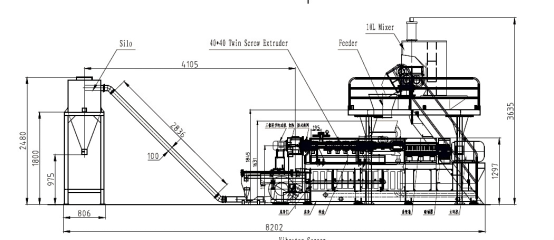

Twin Screw Extruder With Water Ring Hot Face Cutting Pelletizing System

Twin Screw Extruder With Water Ring Hot Face Cutting Pelletizing System has excellent mixing performance, good self-cleaning performance and flexible modular configuration characteristics which make it suitable for processing different types of materials. Extensively used in the following fields:

1、Polymer processing

2、Foods stuff processing

3、Chemical products

4、Various high molecular materials

Application Field of Water ring hot face cutting pelletizing line & two screw extruder for masterbatch.

a. Fiber Reinforcement: Glass fiber, carbon fiber reinforced PP, PA, PBT, ABS, AS, PC, POM, PPS, PET, PPO, PSF, LCP etc.

b. Polymer Blending: blending of PC/ABS, PA/ABS, CPE/ABS, PP/EPDM, PA/EPDM, PP/SBS Etc.

c. Incorporation of Fillers: CaCo3, Talc, Tio2, Carbon black filled PE, PP or EVA etc.

d. Cable Compounds: Cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, MDPE, radiation cross likeable compounds, optical fiber protection compounds heat-shrinkable polymer compounds

e. Special Compounds: PPR pipe compounds PE compounds for cross liked pipes, tobacco filter compounds etc

f. High Concentration Color Masterbatches: PE, ASS, PE, EVA, PET, PP ETC WITH HIGH Concentration of pigments and other processing aids.

g. Masterbatches with Flame-retardants: PP, PA, ABS, EVA, PBT etc. with fame retardants and other additives.

h. Special Functional masterbatches: Masterbatch with anti-static, antic bacteria, or other special functional fillers.

I. Masterbatches for Degradable Polymers: pp, pe, ps ETC. Blended with high concentration of startech and other processing aids.

Advantages Of Water Ring Cutting Line:

Water Ring Cutting Line is special equipment for the PE PP etc.film recycling granulating, it equipped with compacting machine which compound pre- compact the film into smaller granules, then easily feed into screw barrel of extruder, its efficiency is high and can improve production capacity and save labour cost.

It has two vacuum exhuasting mouth on extruder barrel which can fully vent the moisture in the material and hence the final granule quality will be very perfect.

At the end of screw barrel, it equipped with double post fast speed hydraulic non -stop screen changer which can effectively filter out the dirty in the plastic melt.

The pelletizing adopts water flush pelletizing which is easier to operate, and the shape and appearance of granule is good service system.

Before-sale

1,Introduce product in detail

2,Recommend suitable solution offer test

During manufacturing

1,Provide layout and engineering conditions

2,Offer screw plan and related documents

3,Inform the project processing status

4,Insure the product designed in accordance with technical documents

After-sale

1,Provide installation,commissioning and training

2,Offer spare parts

3,Provide necessary technical support and update information