Description

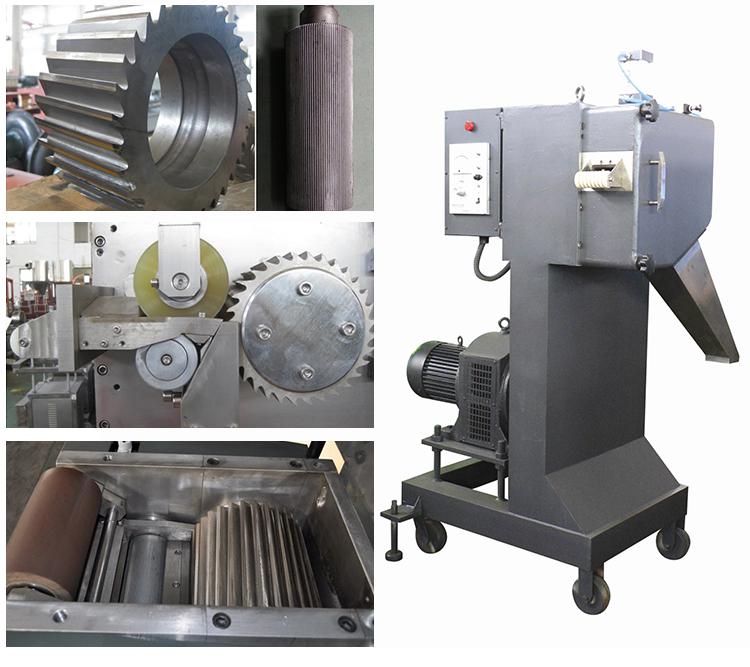

PP plastic granule pellet gantry strand pelletizer for plastic extruder

Strand Sw-600 Gantry Pelletizer for plastics

Capacity: 1200kg/hr

Max cutting no.: 60

Pellets size: Φ3×3mm

Line speed: 96m/min

Rotor size: Φ200×400mm

Kinves no on rotor: 32

Fixed knife size: 400×15×30mm

Rubber roller size: Φ120×400mm

Motor power: 15kW

Speed was controlled by frequency inverter

The gantry pelletizer is supplied with high speed steel and hard alloy steel cutting blades for reliable

performance.

Compact structure allows less maintenance. Production platform is well designed and strong enough

for cooperation. Cutting assembly is featured with quick clean and change over.

Application:

The Cantilever Pelletizer is designed to produce uniform pellets in wide varieties of size for most of any plastic material.

Advantages:

Fit to pelletize glass fibre , minerial, enhanced plastics, rubber mixer, PVC, PBT, PA,PP,PE,PS,PET, ABS and other plastics strand pelletizing.

Anti-wear blades, are made of high quality tool steel ;Electromagnetic speed control; Easy and convenient to operate,just needing to open the top cover when cleaning and maintaining; equipped with mute gear transmission; anti-wear rubber towing stick; The foundation has swivel caster and fixed screw feet , easy to move and fix.

| Model | SW -LQ 60 | SW -LQ 300 | SW -LQ 500 | SW -LQ 900 |

| Max output | 60kg/hr | 300kg/hr | 500kg/hr | 900kg/hr |

| No. of strand | 6 | 15 | 625 | 42 |

| Standard pellet | 3x3mm | 3x3mm | 3x3mm | 3x3mm |

| Cutter dimension | 120x60mm | 120x100mm | 200x200mm | 200x300mm |

| (L*W*H) | 14 tooth | 32 tooth | 32 tooth | 32 tooth |

| Effective rotation speed | 350-1000rpm | 350-1000rpm | 350-1000rpm | 350-1000rpm |

| Haul off speed | 0-36m/min | 0-96m/min | 0-96m/min | 0-96m/min |

| Motor power | 1.5kw | 3kw | 5.5kw | 11kw |

| Rotated cutter clearance | 0.06-0.12mm | 0.08-0.12mm | 0.08-0.12mm | 0.08-0.12mm |

| Leading roller | PU | PU | PU | PU |

| Driver control | Frequency inverter | |||

| AC motor | 3 Phase / 380 V / 50 Hz | |||

| Material of cutter | High-speed Steel / Hard Alloy | |||

service system

support and service-when you need

Before-sale

introduce product in detail

Recommend suitable solution

Offer test During manufacturing

Provide layout and engineering conditions

Offer screw plan and related documents

Inform the project processing status

Insure the product designed in accordance with technical documents

After-sale

Provide installation,commissioning and training

Offer spare parts

Provide necessary technical support and update information