Description

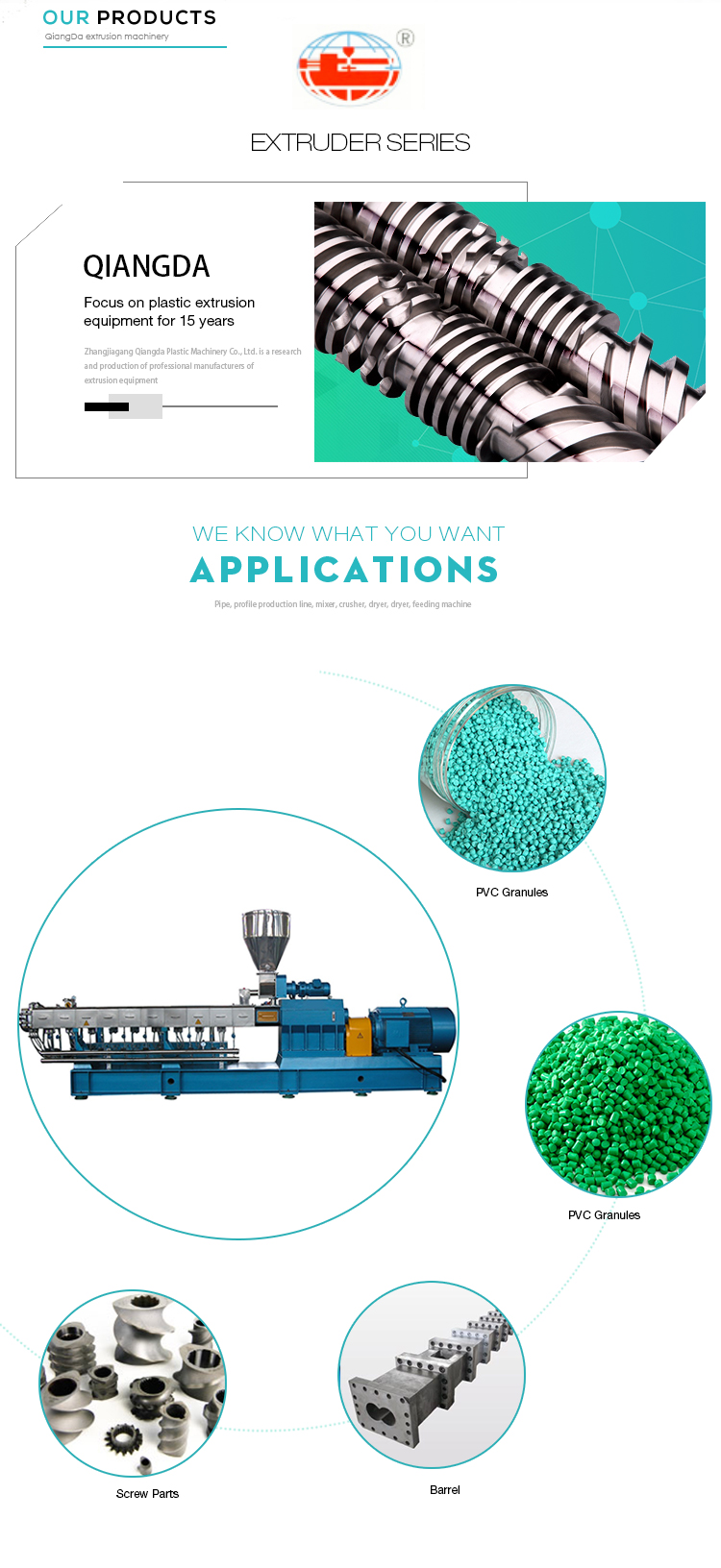

Co-rotating parallel doubel screw plastic extruder machine is a kind of high-efficiency compounding and extruding equipment. Its core section is composed of “00”type barrel and two screws, which mesh with each other. It also has driving system and control system and control system, feeding system to form a kind of special extruding, granulation and shaping processing equipment. The screw stem and barrel adopt building type design principle to change the length of the barrel, choose different screw stem parts to assemble the line according to material characteristics, so as to get the best work condition and max function.

| Model | Screw diam. (mm) | Motor power (kw) | Drawing power

(kw) |

Output(kg/h) |

| Single screw extruder | 45 | 11 | 0.75 | 20 ~ 50 |

| Single screw extruder | 55 | 15 | 1.5 | 40 ~ 80 |

| Single screw extruder | 65 | 18.5 | 2.2 | 60 ~ 110 |

| Single screw extruder | 70 | 22 | 2.2 | 70 ~ 120 |

| Twin screw extruder | SJZ51/105 | 22 | 1.5 | 50 ~ 140 |

| Twin screw extruder | SJZ55/110 | 22 | 2.2 | 50 ~ 140 |

| Twin screw extruder | SJZ65/132 | 37 | 2.2 | 250 ~ 300 |

| Twin screw extruder | SJZ80/156 | 55 | 2.2 | 320 ~ 450 |

SW Adanced Features:

1.Euro-style rectangle barrel makes temperature difference in C areas smaller

2.Innovated design of heater tightened style insures high efficiency of heat transfer and high longevity of the heater

3.Acocording to the material and special technical demands, the material cylinder can use high quality nitrided steel

4.Optimized die head with braker plate.Water cooling pelletizing.

5.The screw elements are designed accuratly and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.

6.The screw configuration,barrel setup,L/D or mode of feeding and venting,screen changing,way of granulating,and control mode can be adjusted according to different material properties.

7.SW 2-stage side feeder, core parts of loss-weight feeder from German.